highlightsFEATURED PRODUCTS

PIONEER IN INNOVATION Forward Hydro Co., Ltd.

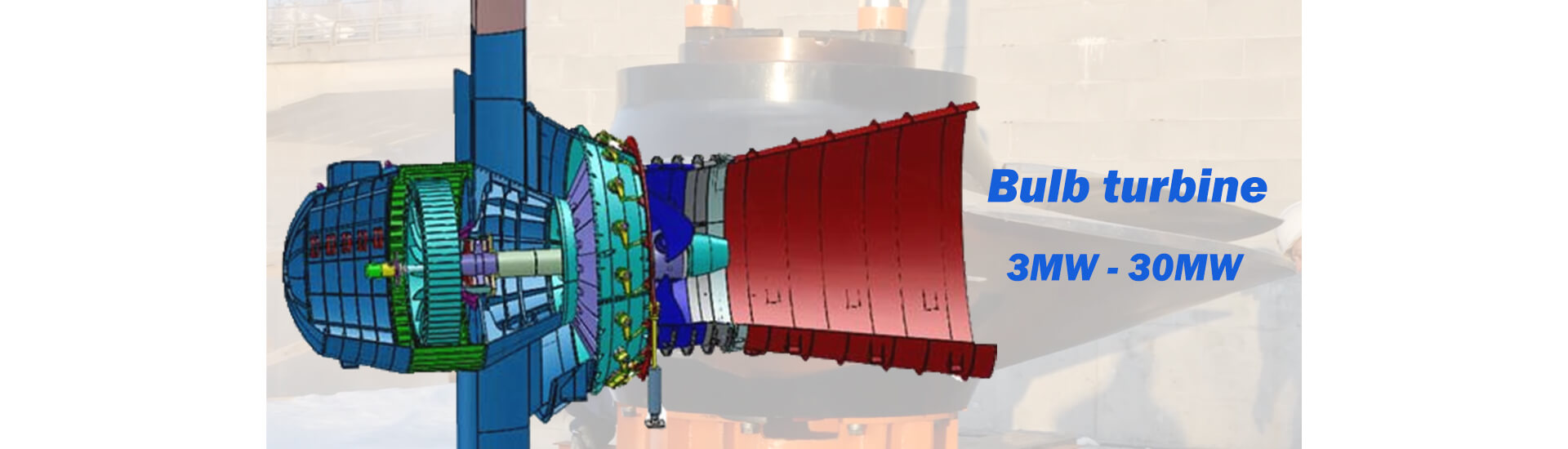

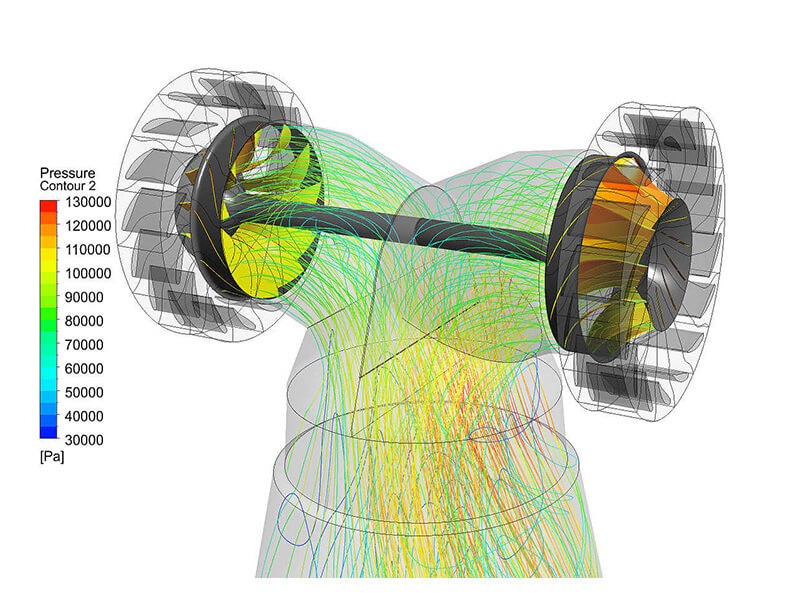

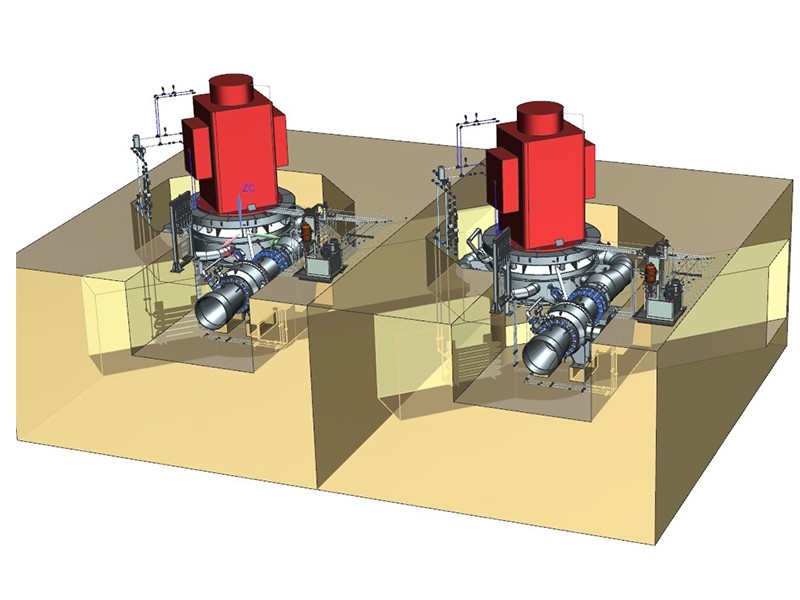

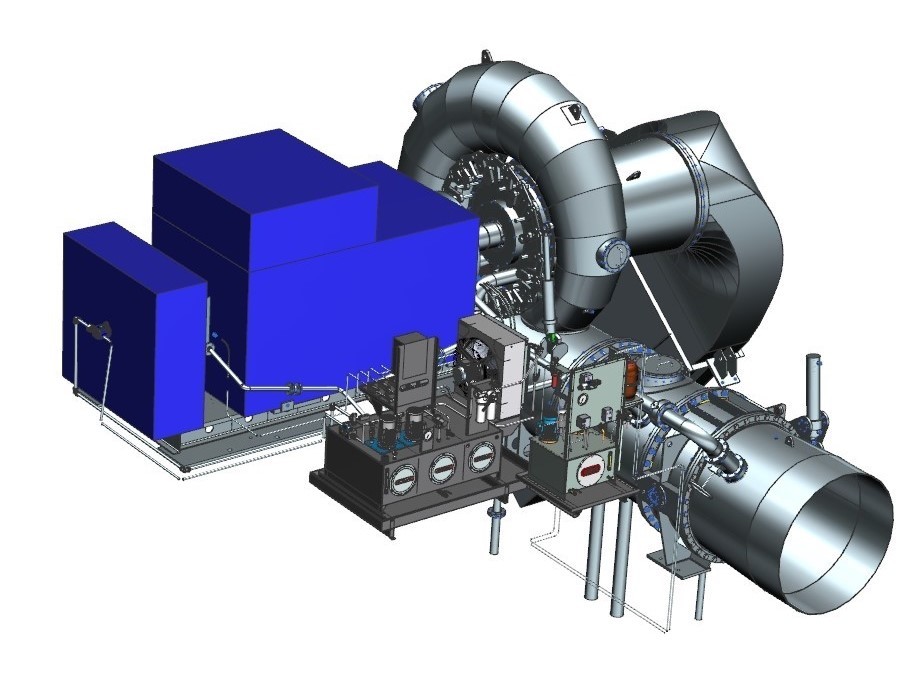

FORWARD HYDRO is a trusted full-line supplier of micro, mini and small hydro power plants up to a capacity of 30 MW per unit and it is one of the very few companies in the world having the know-how that is necessary for the realization of technically perfect deliveries of all important types of turbines, i.e. Kaplan, Bulb, Francis and Pelton. All the equipment is produced exclusively in the facility of Forward Hydro and none of the components are outsourced.

SHARE WHAT YOU CARE Latest News

Reliability AssuranceFrequently Asked Questions