Contact us now for your demand sales@smallhydroturbine.com

Your main benefits when choosing our turbine:

1. Own design and production, wide choice of configurations

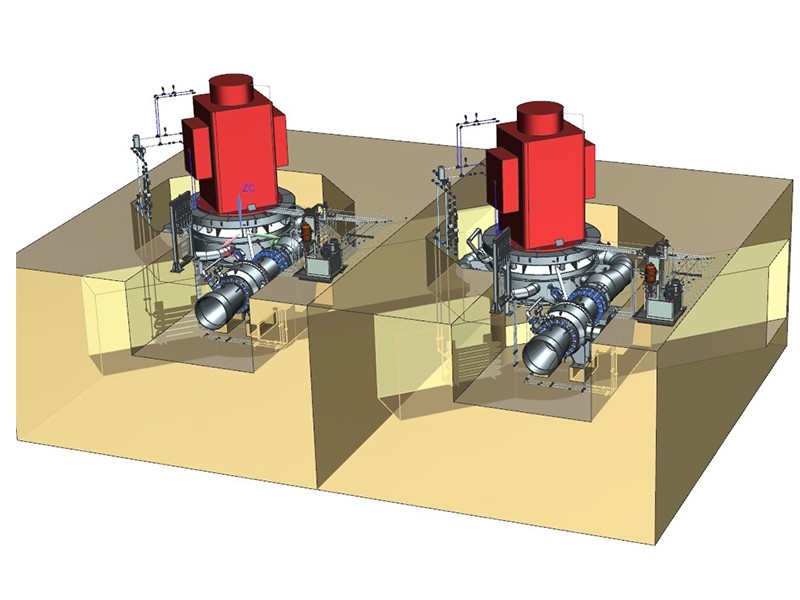

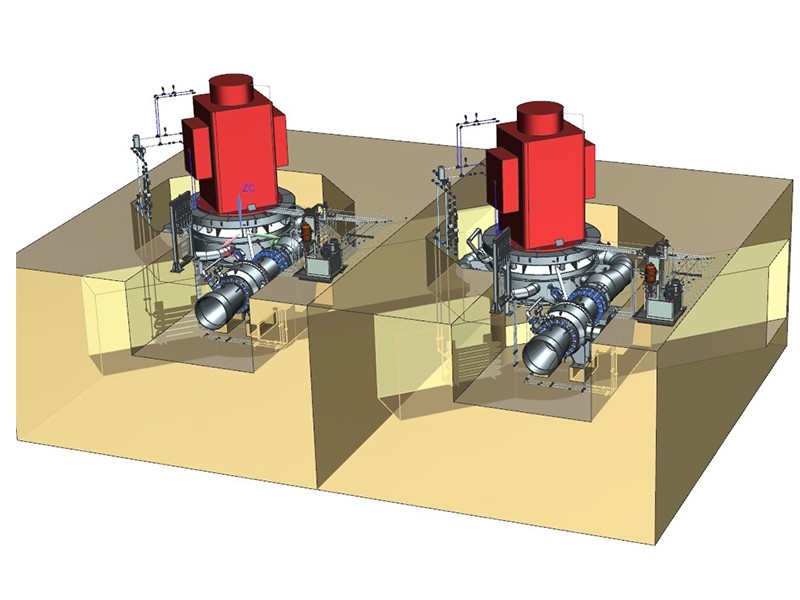

2. 3D modelling for perfect design

3. 5-axis CNC machining for perfect manufacturing

4. Different runner material choices for the best cost benefit result

5. Special heat treatment of runners for very high heads

6. Reliable, standard industrial components for a high lifetime expectancy

High Efficiency Runner

Designed with 3D model and optimized by CFD and FEA calculations. Welded construction, runner blades made of INOX ocr13Ni5Mo, fully CNC machined. Not witnessed tests including dynamic balance and non-destructive inspection. Manufacturing standard accrdoing to EN-DIN.

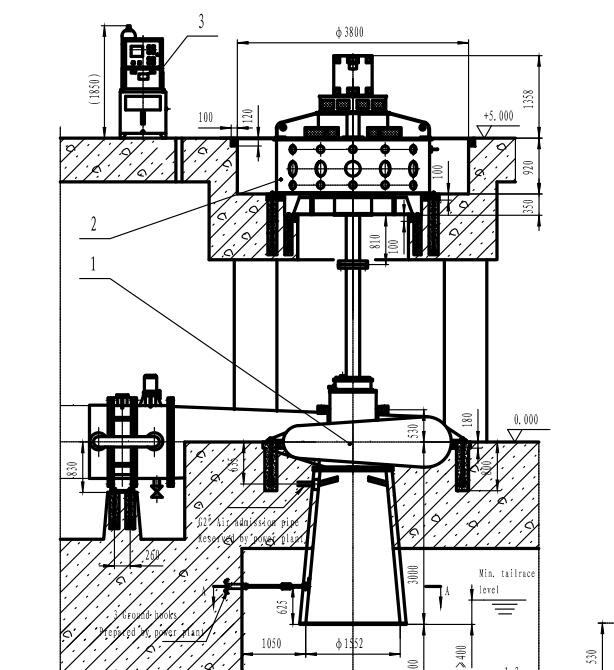

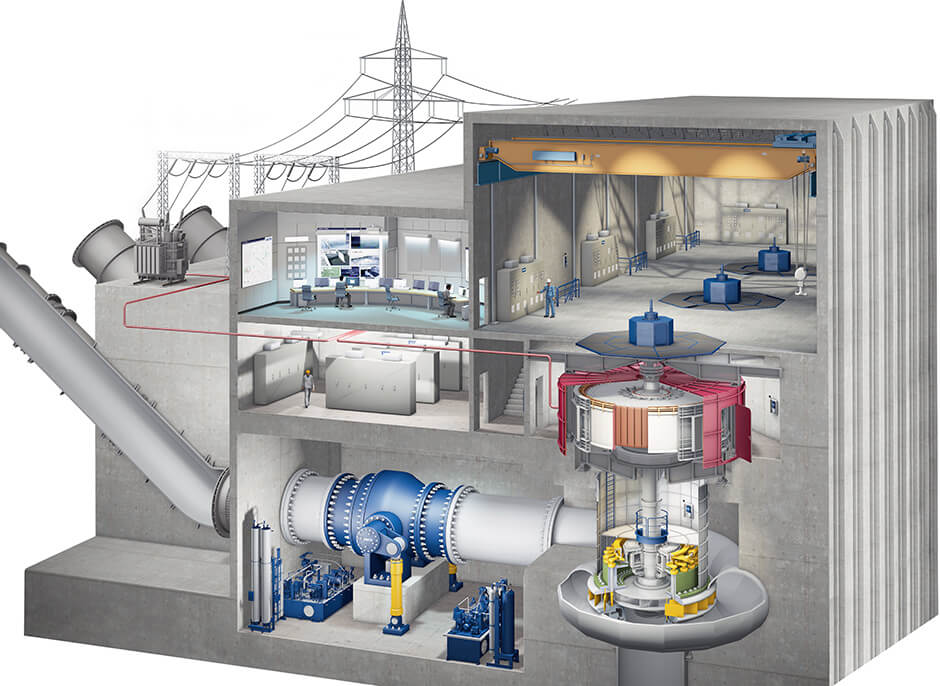

Distributor

The distributor and movable wicket-gate controls water flow towards runner. The mechanism that connects the wicket gates to an operation ring consistes of several parts. The parts are typically made from carbon steel.

Spiral casing

The spiral casing diverts the water flow into the turbine and distributes the water flow evenly around the runner. It is welded in several structural carbon steel setments.

Main shaft

The turbine shaft is made of steel C45E to EN1025-2 and heat treated to relieve the stresses due to manufacturing. The shaft is entirely machined and appropriately finished at the bearing location. For the speed recognition a perforated disc with speed sensor is fixed on the shaft.

Discharge ring and draft tube

The discharge ring has a welded construction with structural ribs at the outer section. The draft tube is shaped according to hydraulic layout of the model turbine. It is made up of several segments of welded steel plates.

Water to wire package

You only provide the powerhouse; we take care of the entire inner workings. Forward Hydro designs, plans, manufactures and produces under one roof everything you need to transform the power of water at the location of your choice into clean electricity; for your usage or for feeding it into the power grid. Investing in a sustainable future could hardly be easier.

InquiryPlease feel free to submit your inquiry information to us. We will contact with you as soon as possible.