Contact us now for your demand sales@smallhydroturbine.com

1. Head range 30 ... 160 m

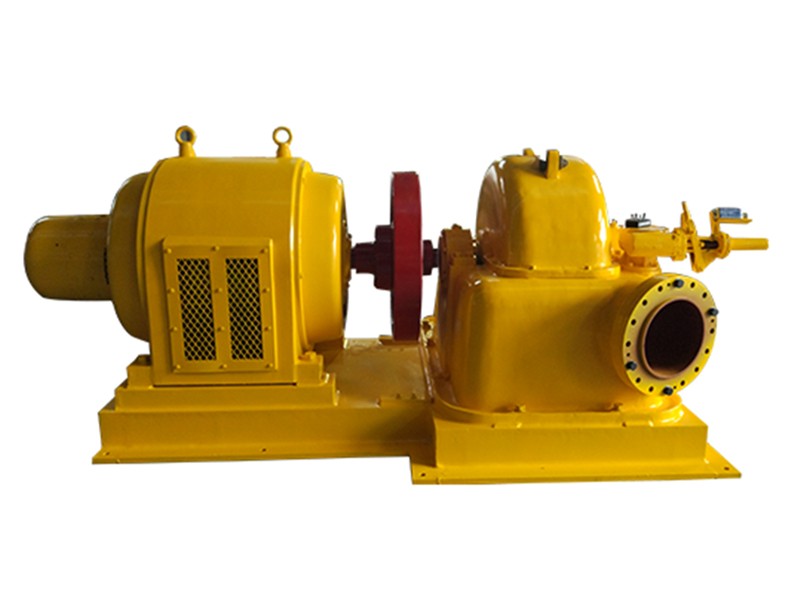

2. Output up to 800 kW

3. Single or double jet design

4. Jet deflectors for outstanding dynamic performance (important on long pipelines)

5. Significantly less sensitive to contamination than Francis turbines

6. Flat efficiency curve shows high efficiency also at partial water flow

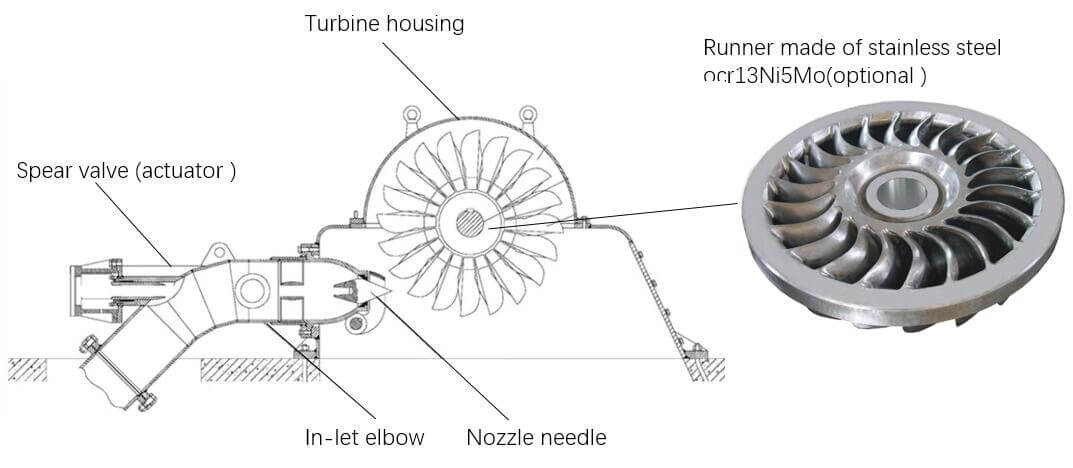

7. Spear valve controlled electrically or hydraulically

8. Runner made of extremely wear-resistant stainless steel – not indestructible, but close to it!

Runner

Designed with 3D model and optimized by CFD and FEA calculations. Welded construction,

runner blades made of INOX ocr13Ni5Mo, fully CNC machined. Not witnessed tests

including dynamic balance and non-destructive inspection.

Manufacturing standard accrdoing to EN-DIN.

Nozzle Jet

The water injection mechanism consists of spear valve, nozzle jet, needle jet, it is water flow

regulate mechanism of the Pelton turbine, the whole mechanism is moved by servomotor.

Deflector is equipped on needle valve to stop the water flow immediate,

it is hydraulically or electronically controlled

Turbine casing

The turbine casing including upper cover part and lower frame casing, they are mounted together

by bolts. With this strucutre, the turbine casing is easy to dismantal during maintenance.

They both are made of casted carbon steel C45E, the surface is polished and painted.

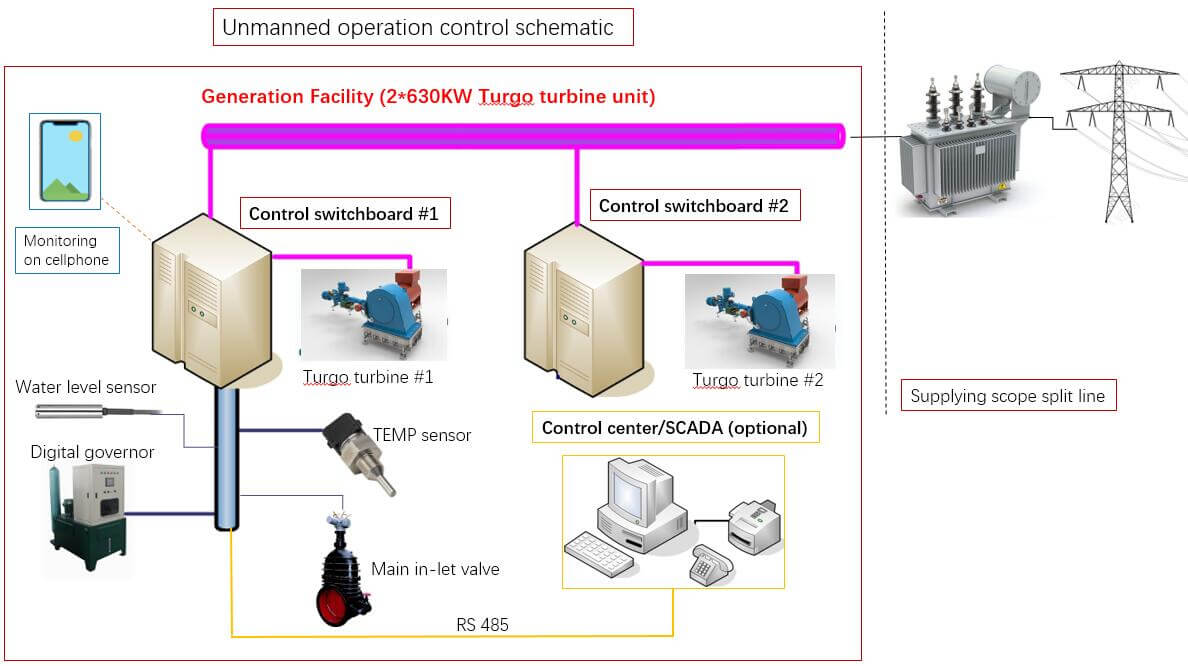

Water-towire package

You only provide the powerhouse; we take care of the entire inner workings. Forward Hydro designs,

plans, manufactures and produces under one roof everything you need to transform the power of

water at the location of your choice into clean electricity; for your usage or for feeding it into

the power grid. Investing in a sustainable future could hardly be easier.

InquiryPlease feel free to submit your inquiry information to us. We will contact with you as soon as possible.